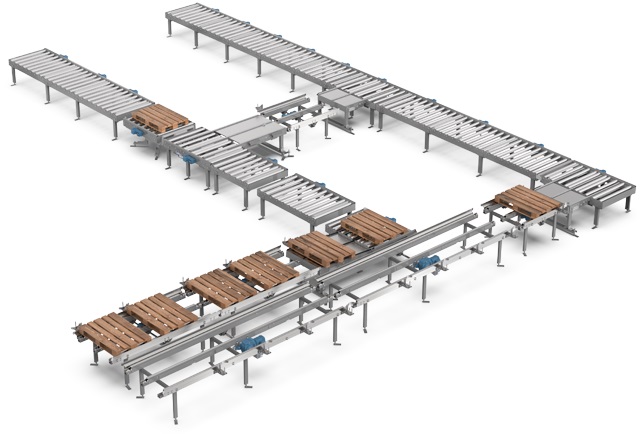

Integrated / dedicated palletizing cells, with robot and automatic and programmable palletizing system. Designed specifically for the customer's needs, they can manage from one to five pallets with 5 products at the same time, with just one robot. However, pallets of different sizes and materials can also be managed simultaneously. The systems can be completed with labeling machines or markers that determine the identification of the pallet. We supply the conveyors for the product to be palletized and the conveyors for the pallets. It is possible to integrate pallet wrappers for stretchfilm and provide software interfaces for integration with automatic shuttles such as AGV or LGV from any supplier.

| Ask more | Catalogue |

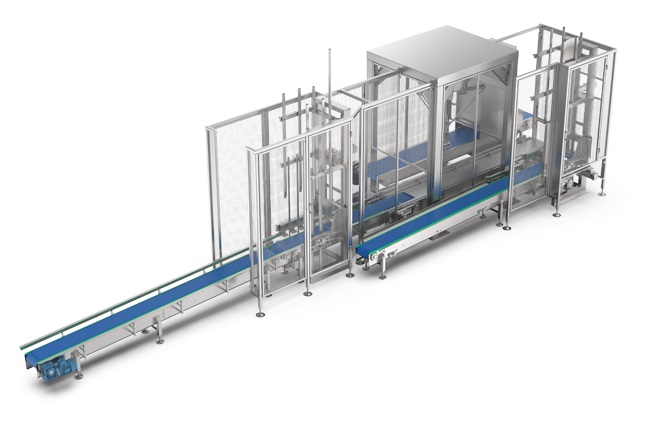

The products are boxed using robotic systems that can use both flexpickers (link to flexpicker) and anthropomorphic robots as in the boxing of the bags of the 4 pan jumps. The systems are particularly flexible in terms of size and scope of the products to be packaged and are solutions that are always customized according to the customer's needs.

Complex palletizing systems with robots system operating automatically, with the possibility of palletizing multiple lines on the same robot and management of complex systems with the production of multiple pallets at the same time. The system is always designed according to the particular needs of the customer in terms of products, types and palletizing schemes, speeds and available spaces. It is possible to supply systems that work in extreme conditions such as cold storage rooms at -30 ° C. The systems are always integrated by Stim which also takes care of the management of the product codes and the packages that are managed, being able to guarantee perfect traceability of the product from the entrance to the plant to the finished pallet. All palletizers can be completed with code reading systems (QR bar etc.) or vision systems for quality management and packaging integrity detection. The gripper grippers of the robots are always adapted to the products to be handled in order to guarantee their grip and precise positioning and avoid any damage.