Depending on the model, components and systems for extraction, sifting, dosing and weighing of powders and liquids from silos and hoppers, suitable for: Baby and functional food, Bakery and biscuits, Beverages, Cacao, Cereals, Chemical, Chocolate, Confectionery, Confectionery Eggs, Dairy, Eggs, Flour, Glucose and syrup, Oil & fats, Pasta, Pet Food, Premix, Salt & Additives, Sugar, Yeast & sourdough.

| Ask more | Catalogue |

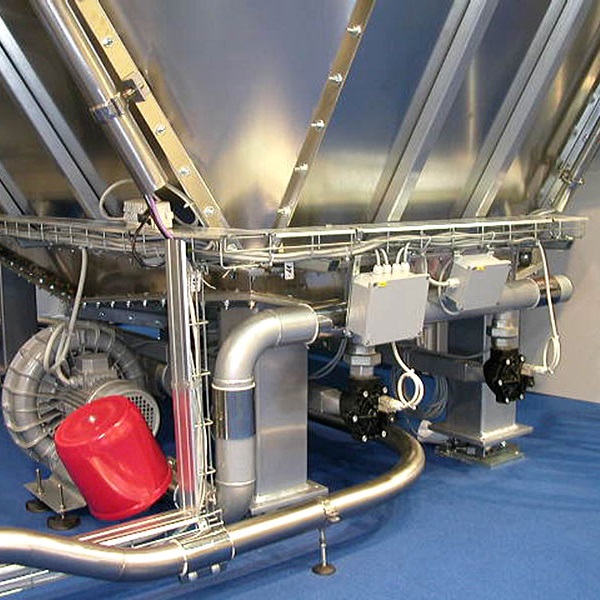

Pneumatic conveyance of powders and granular products and pumps for liquid products. Pneumatic conveyance of powders and granular products, by suction or low pressure compression or dense phase, and mechanical conveyance with feeding screws, belts and chains. Centrifugal and volumetric pumps for liquid products. Pipes in stainless steel, insulated or heated. Lift deviator to separate pneumatic lines, with integrated transition and all parts coming in contact with the product in stainless steel. Gravity deviators with one or more ways to discharge on hoppers and mixers. Safety systems including overpressure valves on silos, CEPATIC system on loading, dispersing valves, magnets, pressure switches and sensors. Slide valves to stop the propagation of explosions and flames in the conveying system. Air is fully sanitised with filtering system, automatic removal of leftovers and CIP washing system. Integrated automation of all conveyance and safety operations and control of all utilities on touch panel. Our conveyance system are designed to optimise energy consumption with an individual analysis of energetic impact. We only employ high-efficiency motors such as IE3 motors to save energy and reduce CO2 emissions.

Components and systems for the single or multiple extraction of powders and liquids from silos and hoppers. Extraction from silos can be single or multiple with multiline distributor, on vibrating cone or fluidization system for a more continuous movement of product. Rotary and butterfly valves for pneumatic conveyance and feeding screws for accurate metering from silos and hoppers. Extraction systems for microingredients on dosed container, fixed or mobile according to the needs of product and process. All extraction systems are completely automated for a chronological emptying and can be controlled on touch panel for maintenance.

Sifting systems for powders to ensure food security, for pneumatic or gravity conveyance and for extraction cones. Vibrosifters for pneumatic lines of variable size and capacity, equipped with container and sieving net in stainless steel, supporting structure in painted steel, conveying reduction to avoid the formation of stale product, automatic removal of impurities on the expulsion channel, connection to pneumatic line in and out, antivibration devices and vibrating group with motovibrator. Vibrosifter for lines in gravity with double sifter, equipped with container and sieving net in stainless steel, supporting structure in painted steel, conveying reduction to avoid the formation of stale product, automatic removal of impurities on the expulsion channel, entry from high and double exit, antivibration devices and vibrating group with motovibrator. Sifting kit for extraction cones with sieving net and fixing ring for dump stations.

Systems for the weighing and metering of powders and liquids at the end of the line, through modular hoppers for powders and tanks for liquids controlled by electronic metering scale for the weighing. Metering can be continuous or batch, positive, by loss of weight, by volume or by weight. High precision metering of micro ingredients such as salt, improvers, aromas, spices, starch, inclusions, and other additives. Preparation, storing and metering of salt solution and invert sugar. Cold and hot metering of fats. The metering process is coordinated by an integrated automation system including touch panel managing the production process (recipe management, production, product and hopper parametrization) and our TRACKING SYSTEM software for full traceability with digitalization through barcode of the movements of all ingredients. Our TRACKING SISTEM includes recipe, ingredient and warehouse managers, and analysis of production history.

The 3 in 1 (weighing, filtering, blending) weighs the ingredient, separates air from product during pneumatic transport and at last blends, all in single unit. The vertical blender inside is a system for the production of premix that ensures the highest flexibility across a wide range of food sectors. It is fast, accurate and clean, delivering a homogeneous mix of powders even for quantities lower than 1% in the span of 3-5 minutes. It can dose in the mixer in a single solution or by loss of weight in small batches. The blender is fully automated and optimizes mixing and production times, as the blend is already homogenous before reaching the mixer. The 3 in 1 can be used in place of the dosing hopper, and its speed makes it very suitable for continuous mixing systems. In installations with multiple lines it can be combined with hoppers to achieve the highest flexibility in production. Available in sizes from 60 to 1000 liters, it can be loaded pneumatically or by gravity. It is equipped with slide valve and extraction is by with rotary valve or feed screw. The 3 in 1 is made in stainless steel and is ATEX conform. Hygienic design with total dischage, easy to clean, fully inspectable and washable. Integrated automation and full traceability.

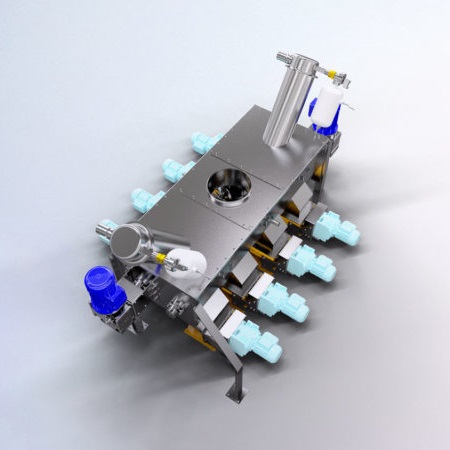

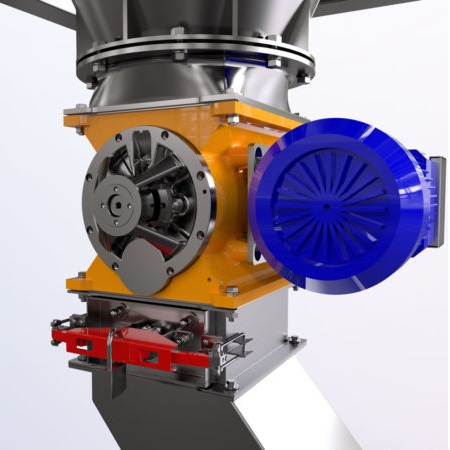

Extraction and metering machine. Suitable for all powders with flushing for abrasive products. Ensures accurate metering on pneumatic conveyance lines. Varying size and capacity. Gravity unloading available.

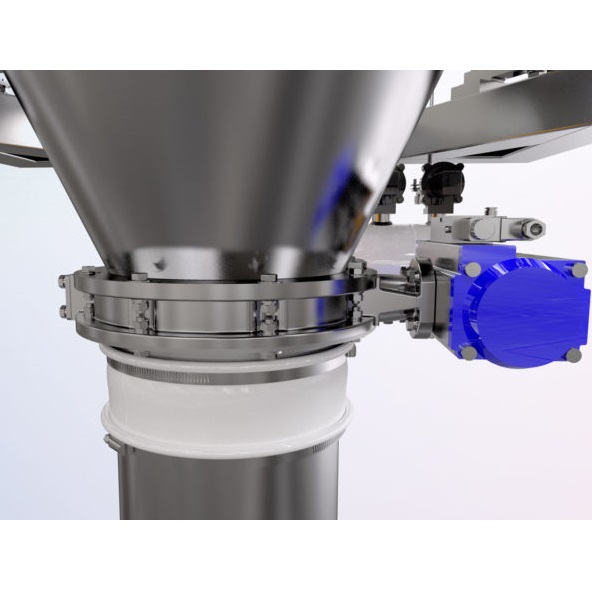

Extraction and locking machine that ensures leak-tightness up to a 1.5 bar. No leaks and no loss on loading. Suitable for all powders and abrasive products thanks to the gasket in long-lasting anti-abrasive rubber. Body in cast iron, disk in stainless steel, inductive limit switch, double acting pneumatic actuator and inductive limit switch. Operating temperature up to 100°c.

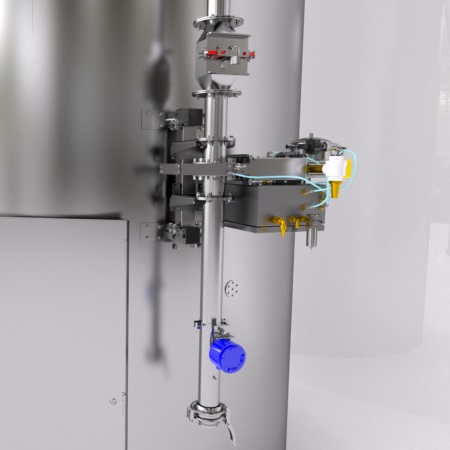

Line diverter for pneumatic conveyance lines, with separate ways to avoid contamination in the product. Suitable for all powders.

Anti-explosion protection system which rapidly insulates the container to stop the propagation of the event. Can be installed on pneumatic conveyance both by suction and pressure. Suitable for all powders, including abrasive ones.

Safety system to avoid contamination from metal parts and damage to machinery removing extraneous matters from equipment installed downstream. Magnets are covered with a detachable pipe and do not come into contact with the product. Easy to clean and suitable for all powders.

Extraction machine to break lumps to ensure homogeneous product in pneumatic conveyance lines. Suitable for all products that form lumps and typically used with sugar storage.

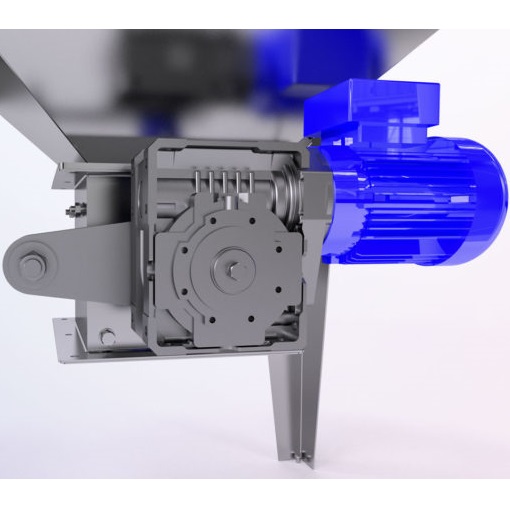

Extraction machine to distribute product from a feeding point entry up to 8 on pneumatic conveyance lines. Suitable for all powders and conform to ATEX legislation.